C201 PROFIsafe

Without SD

With SD

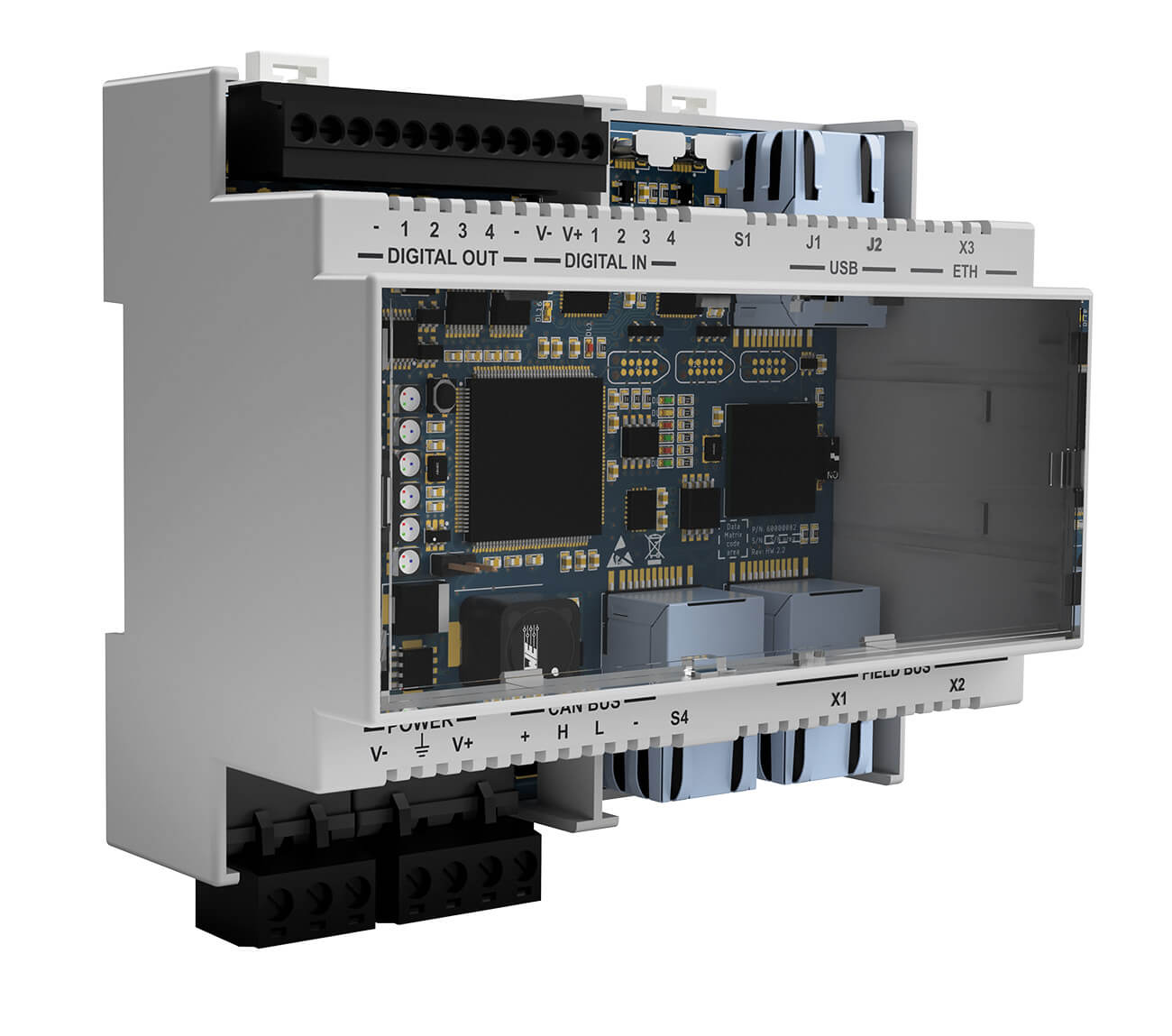

C201 is the most advanced control unit

with the widest range of communication options (PROFIsafe, MODBUS and digital I/O).

Without SD

With SD

Quickly learn how to set up our products

These short tutorials are ready to unveil every aspect of our Smart Sensors. Watch, learn, and become an expert in no time.

Safety Fieldbus

The Ethernet Fieldbus permits connection between the control unit and the PLC that controls the machine, to exchange complex information, such as real time operator position, allowing rapid integration with machinery fieldbuses.

Dynamic setting of detection fields

With the C201 PROFIsafe it is possible to change the detection field dynamically by selecting in real time one of the 32 available configurations. This feature is particularly useful in mobile applications, like AGV (Autonomous Guided Vehicles) and MIR (Mobile Industrial Robots) applications.

Secure ethernet configuration

Remote configuration and management protected by industry standard cyber-security protocols.

Digital inputs

Two dual channel inputs which support the following functions:

- restart signal

- muting signal

- dynamic configuration switch

- system recondition

- stop signal

The following functions can also be used as single channel:

- restart signal

- system recondition

Safety outputs

Two dual channel safety outputs for the detection signal, either for one or more detection fields or four digital OSSD outputs used individually (non safe) which can be configured as:

- system diagnostic signal

- restart feedback signal

- muting enable feedback signal

Muting function

The system can be configured to temporarily inhibit the capability of one or more sensors, avoiding an alarm status when a movement is present in their field of view.

Maximum flexibility.

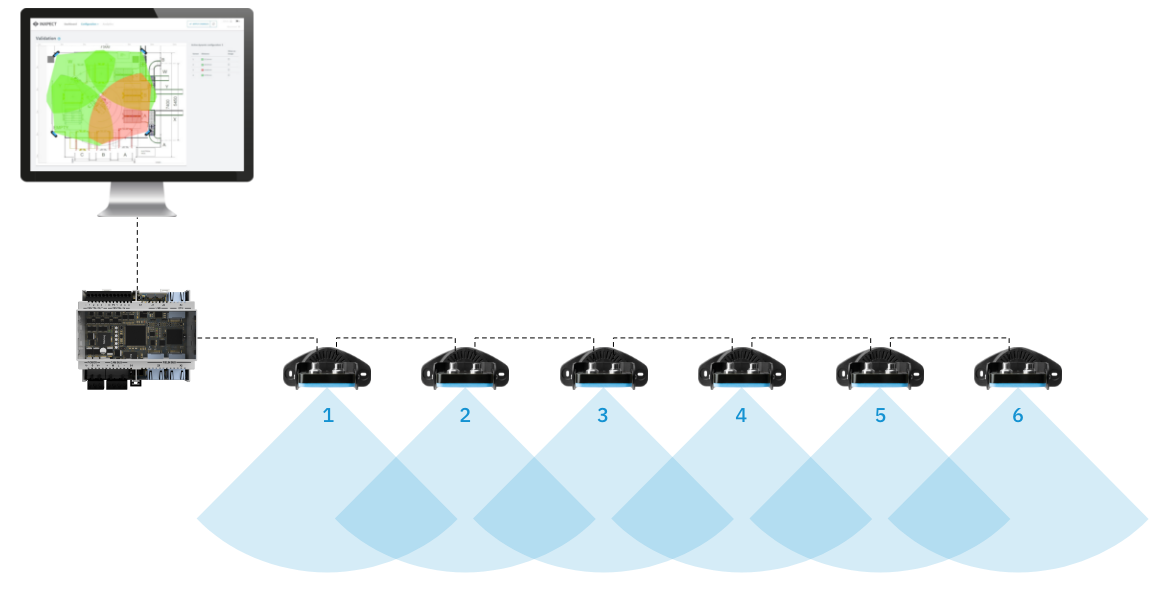

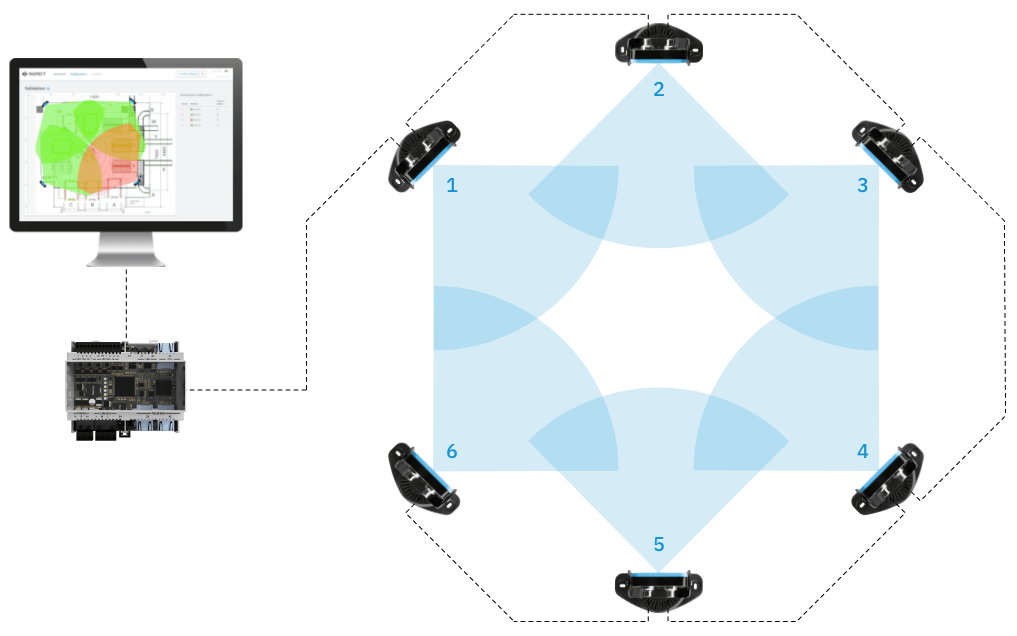

One control unit, from one to six sensors: small to large, simple to complex, a solution for every requirement.

- Automatic background detection and removal allows the system to adapt itself to changing conditions in the work area.

- The software supplied with the system allows for multiple configurations: assisted automatic configuration for regularly-shaped areas and manual configuration for monitoring more complex areas.

- Programmable muting allows the creation of differentiated intervention areas where operators can gain safe access according to production logic.

Without SD

With SD

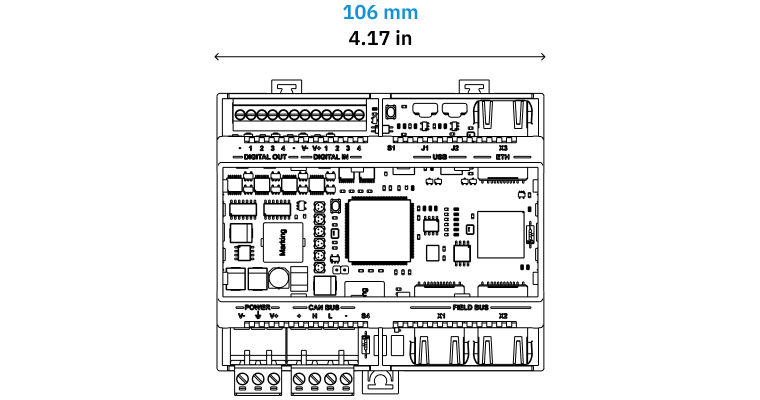

Technical details

| CONTROL UNIT 200 SERIES (C201A-PNS | C201B-P) | |

| Outputs | 4 Outputs Signal Switching Devices (OSSDs) or 2 dual channel safety outputs |

| Safety outputs | High-side outputs (with extended protection function) Max voltage: 30 V dc | Max current: 0.4 A | Max power: 12 W |

| Inputs | 2 dual channel TYPE3 digital inputs with common GND 4 single channel TYPE3 digital inputs with common GND [from FW 2.0.0 onwards] |

| Fieldbus interface | Ethernet based safety fieldbus (e.g. PROFIsafe) |

| Modbus interface | Ethernet interface for real time data monitoring |

| Power supply | 24 V dc (20–28 V dc) Max current: 1 A (no OSSD) |

| Max power consumption | 5 W (no OSSD) |

| Assembly | DIN guide |

| Degree of protection | IP20 |

| Terminals | Section: 1mm2 | Max Current: 4 A with 1mm2 cables |

| System configuration | Ethernet, USB |

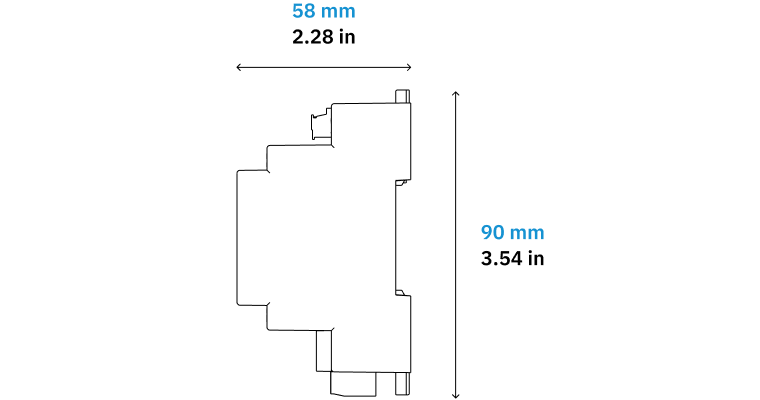

Dimensions

Without SD

With SD