S101A The first safety radar sensor

4m

Range sensor

10s

Restart timeout

1.6m/s

Max target speed

The first safety radar sensor in the world

with SIL2 certification for use in industrial safety applications.

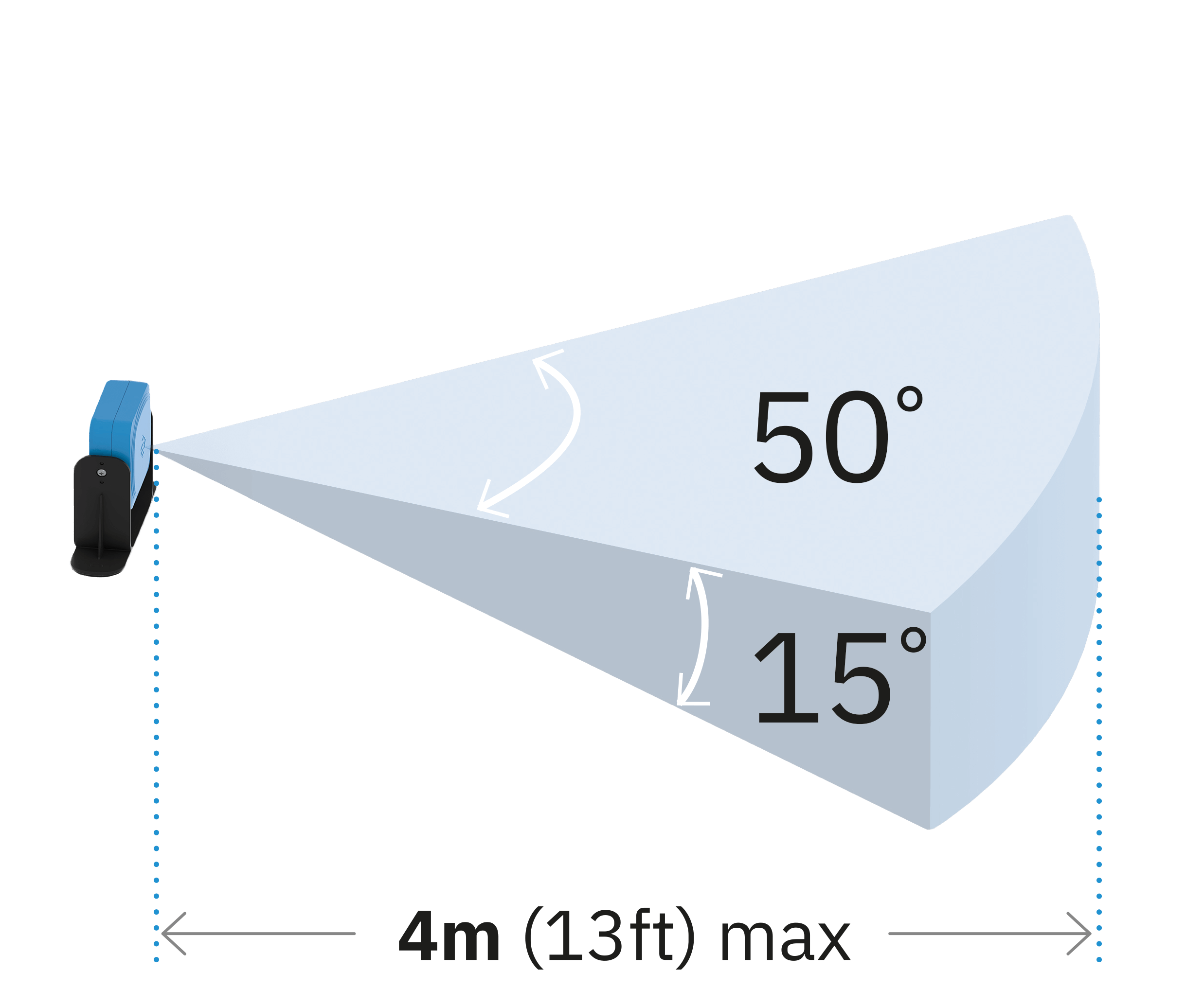

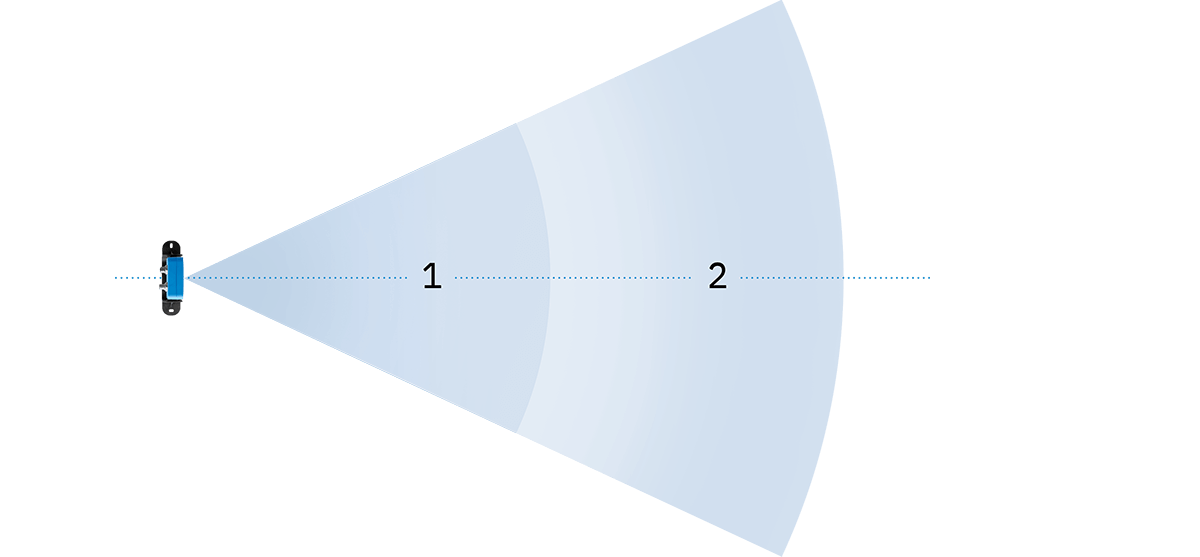

Two configurable fields of view

Narrow FOV

0 - 4 m

[min. set distance: 1m]

Horizontal Plane: 50°

Vertical Plane: 15°

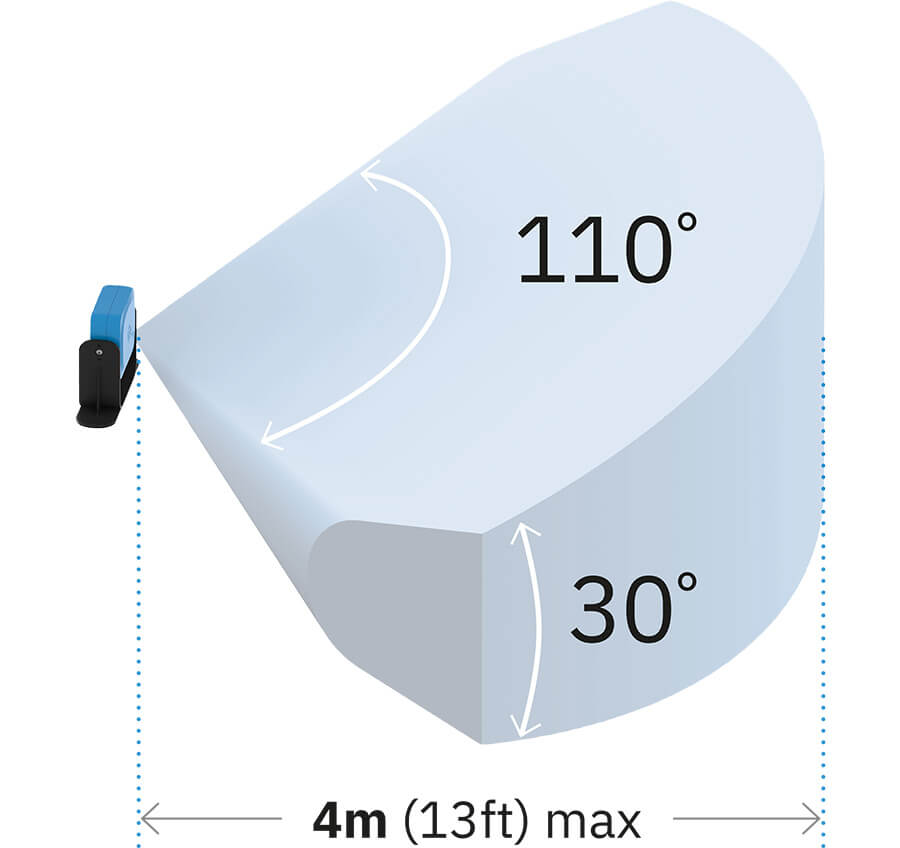

Wide FOV

0 - 4 m

[min. set distance: 1m]

Horizontal Plane: 110°

Vertical Plane: 30°

Two detection fields

Two detection fields with fixed angles (angles can only be wide or narrow).

Quickly learn how to set up our products

These short tutorials are ready to unveil every aspect of our Radar Sensors. Watch, learn, and become an expert in no time.

Immune to light

Immune to debris

Immune to smoke

Immune to fluids

Safety functions

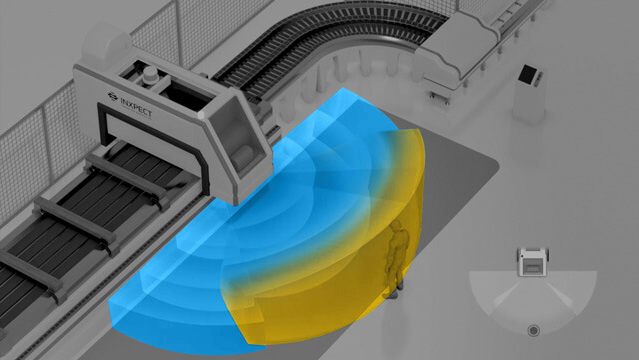

Access protection

First safety function: a 3D, configurable virtual barrier with two different detection fields, providing a secure signal to control machinery.

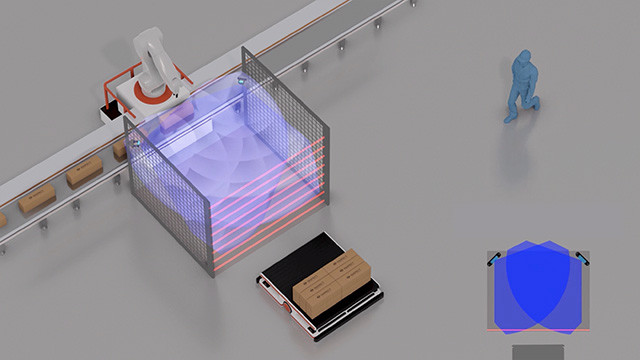

Restart prevention

Second safety function: safe presence sensing to prevent machinery from starting as long as operators are in dangerous areas.

3d scanning

Radar functions natively in 3D, and can therefore protect dangerous areas volumetrically. Operators cannot elude detection by radar no matter how hard they try!

SIL2/PLD certificates

S101A sensors are the first (and the only one to date) radar sensors in the world that have obtained SIL2 certification for use in industrial safety applications.

Robust to environmental disturbances

A radar sensor is extremely resistant to environmental disturbances. This makes it possible to work without false alarms in environments where there is smoke, dust, water and machining swarf.

High-sensitivity detection

When a sensor detects an operator entering a dangerous area, it starts to function in high-sensitivity mode, which also detects operator micro-movements from breathing and prevents accidental machine restart.

Technical details

| RADAR SENSOR 100 SERIES (S101A) | |

| Frequency | 24 GHz ISM license-free |

| Connectors | Two 5-pin M12 connectors (1 male and 1 female) |

| CAN bus termination resistance | 120 Ω (not supplied, to be installed with termination connector) |

| Power supply | 12 V dc ± 20%, through control unit |

| Power consumption | 1.5 W |

| Degree of protection | IP67 |

| Operating temperature | From -30 to +60 °C (-22 to +140 °F) |

| Case material | Sensor: PA66 | Bracket: PA66 and glass fiber (GF) |

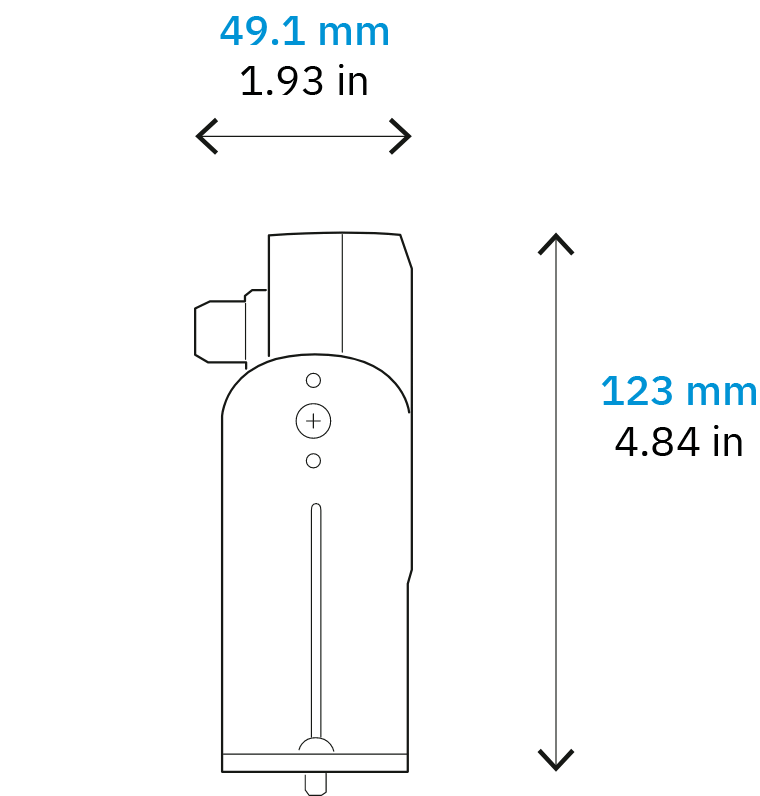

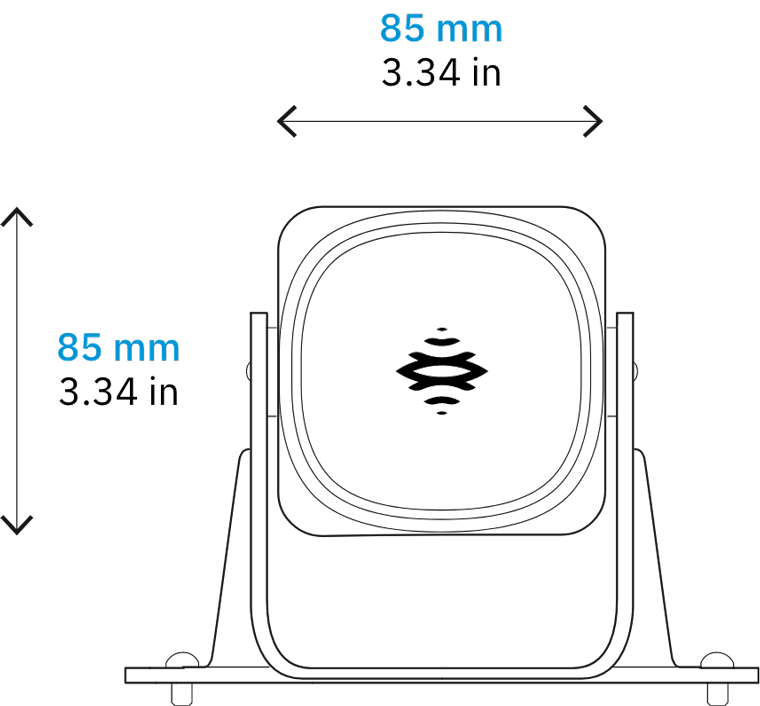

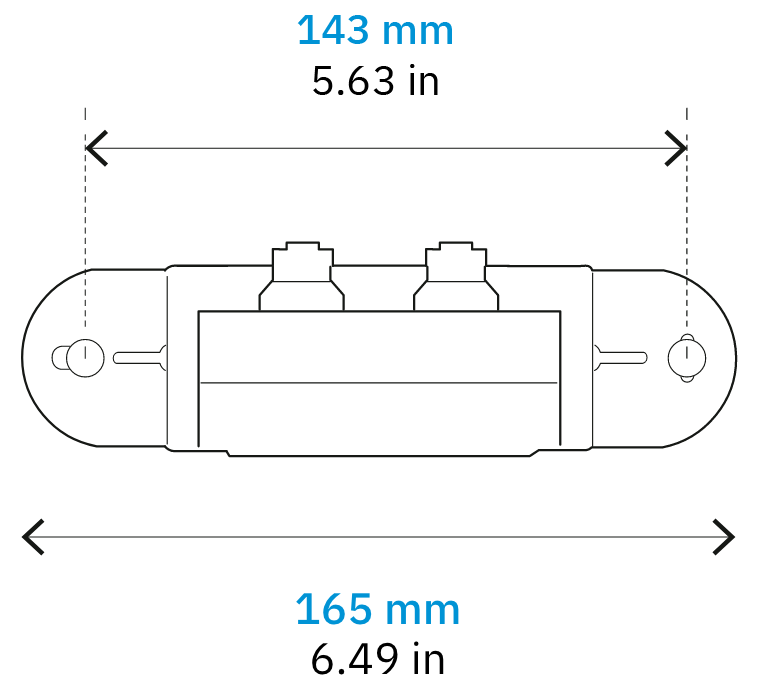

Dimensions

Want more information?